Delivery Partner is like a life partner for your business!

Choose the right one, and your business soars with smooth operations and happy customers; choose the wrong one, and you risk delays, losses, and frustration at every step.

If you want to grow your business internationally, selecting a reliable delivery partner is vital. You need a partner who can take care of your delivery from your door or warehouse to the place you are shipping. Choosing a logistics provider isn’t just about choosing the cheapest quote; it’s about ensuring reliable, consistent, and damage-free deliveries.

Consider this blog your compass in the vast world of logistics, pointing you toward the performance metrics that distinguish trustworthy shipping partners from the ones that could jeopardize your business. But before we dive into the numbers, let’s first understand what sets a good international shipping partner apart from a bad one.

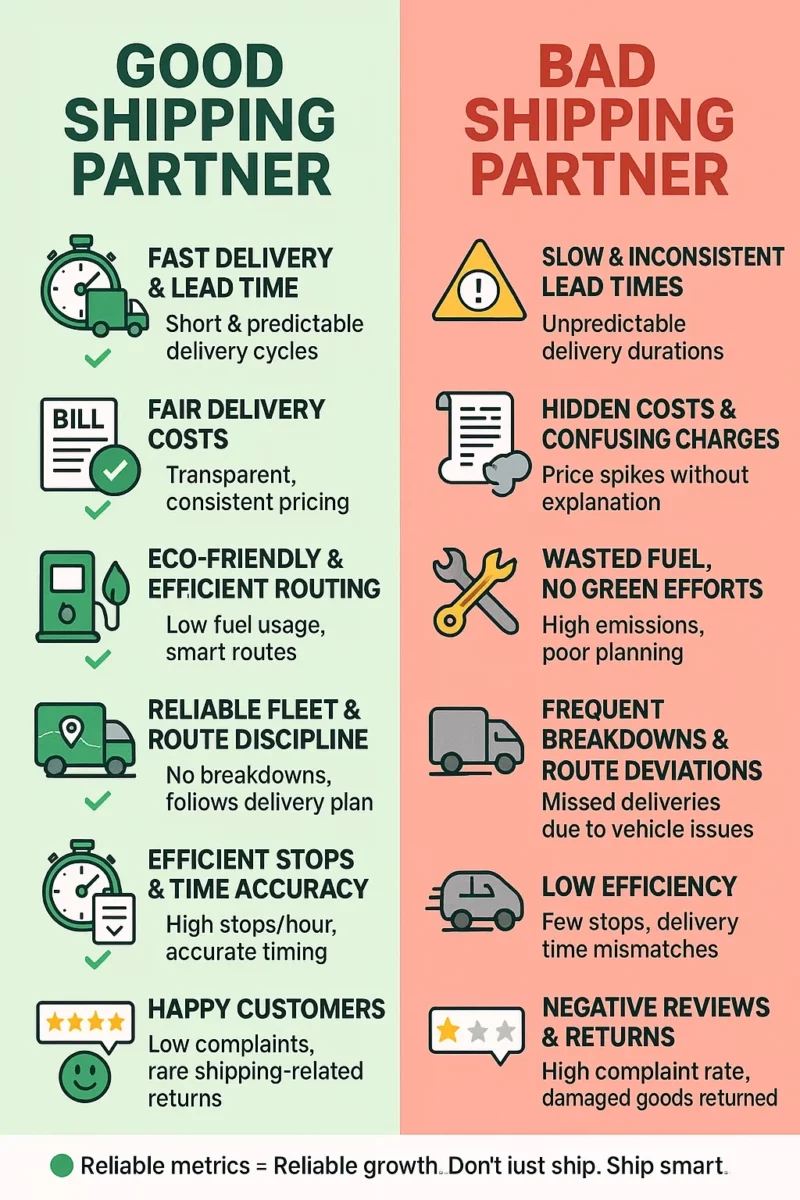

Good Shipping Partner vs Bad Shipping Partner

A good shipping partner consistently maintains a high on-time delivery rate (95% or above), adheres to promised delivery schedules, and ensures your shipments arrive on time and in full (OTIF). They deliver the right products, in the right quantity, and with accurate documentation, leading to high order and shipping accuracy.

You’ll see a high perfect order rate, meaning orders are not just timely, but also damage-free and well-documented. Their first attempt delivery success rate is strong, reducing failed deliveries and frustrated customers. Metrics like average delivery time and lead time are predictable, consistent, and supported by transparent tracking systems.

Financially, a good partner provides a fair and clear cost per shipment, without surprises or hidden fees. They also optimize fuel consumption and mileage, reducing costs and environmental impact. Their fleet is reliable, with a low vehicle breakdown rate, and drivers follow assigned routes with high route adherence.

In contrast, a wrong partner shows frequent delays, missed deliveries, packaging issues, high complaint rates, and even returns due to shipping problems. They may offer low prices upfront, but cost you much more in lost business, customer dissatisfaction, and brand damage.

Ultimately, the difference comes down to data-backed performance. Don’t just go by promises, ask for metrics. Your shipping partner is an extension of your brand. Choose wisely.

If you dream of your shipments arriving on time, in full, and in perfect condition every single time, then these are the must-know signs that will lead you to the right delivery partner for your business journey.

| Criteria | Good Shipping Partner | Wrong Shipping Partner |

|---|---|---|

| On-Time Delivery Rate | 95%+ on-time with tracking | Frequent delays, no tracking |

| Delivery Schedule Adherence | Sticks to committed schedules | Misses timelines without notice |

| On-Time In-Full (OTIF/DIFOT) | Orders complete and on time | Partial/missing item deliveries |

| Order & Shipping Accuracy | Zero errors in items & docs | Frequent errors & wrong info |

| Perfect Order Rate | 95–99% flawless deliveries | Late, damaged, incomplete orders |

| Delivery Condition Metrics | Clean, intact packaging | Damaged, crushed packages |

| First Attempt Delivery Success | 90%+ first-time success | High failed delivery attempts |

| Average Delivery Time | Fast and consistent timelines | Slow and unpredictable timing |

| Lead Time Metrics | Clear from dispatch to delivery | Unclear or inconsistent lead times |

| Cost per Delivery / Shipment | Fair and transparent pricing | Hidden charges, unclear bills |

| Fuel Consumption & Mileage | Optimized routes & green fleet | Wastage, high emissions, no planning |

| Vehicle Reliability | Well-maintained, minimal breakdowns | Frequent failures, delayed deliveries |

| Route Adherence Rate | Drivers follow planned paths | Frequent deviations, inefficient routes |

| Stops per Route Hour | High efficiency & deliveries per hour | Fewer stops, poor time utilization |

| Delivery Time Variance | Minimal deviation from ETA | Major delays without reason |

| Complaints, CSAT & Return Rate | Low complaints, high CSAT, rare returns | Frequent issues, poor CSAT, many returns |

1. On-Time Delivery Rate and Delivery Schedule Adherence

For an exporter, delays can damage customer trust and even result in returns. The on-time delivery rate shows the percentage of shipments that reach the customer within the promised time window.

Delivery schedule adherence goes a step further by measuring how consistently a shipping company sticks to the planned delivery schedule. A partner with a high adherence rate is predictable and dependable.

Why should you care: You should choose partners with a high on-time delivery rate and schedule adherence because they reduce the chances of your products arriving late or missing key market deadlines.

Red Flags:

- Frequent delays without proper communication

- Delivery windows are regularly missed by several days

- Vague timelines with no delivery performance history

2. On-Time In-Full (OTIF/DIFOT)

The on-time in-full or DIFOT metric ensures that all items in an order are delivered completely and on time. A good OTIF score tells you that you can trust the provider to deliver what I promise to my customers. Sometimes

Why it matters to you: A missed item or split shipment leads to confusion, extra costs, and dissatisfied buyers. Always prefer shippers who consistently hit high OTIF marks.

Red Flags:

- Partial deliveries are becoming a regular occurrence

- Frequent missing items in shipments

- Customers reporting incomplete orders often

3. Order Accuracy and Shipping Accuracy

Order accuracy tracks how often the right products in the right quantities are picked, packed, and shipped. Shipping accuracy measures whether the shipment reaches the correct destination with the correct documentation.

What you should look for: High scores in both mean fewer errors, lower return rates, and better customer experiences. It also helps avoid customs issues during international shipping.

Red Flags:

- Incorrect items or quantities delivered

- Frequent address or documentation errors

- High rate of customs delays due to poor paperwork

4. Perfect Order Rate and Shipping Accuracy

The perfect order rate combines multiple metrics: on-time delivery, full order completion, zero errors, and no customer complaints. It gives a complete view of how flawless a logistics company’s performance is.

What you should look for: Always ask shipping partners for this number. If it’s above 95%, that’s a green flag.

Red Flags:

- Regular incidents of damaged, late, or incomplete orders

- High volume of customer service follow-ups or escalations

- Partners are unable to share or track this metric

5. Delivery Condition Metrics and First Attempt Delivery Success

Delivery condition metrics track the quality of the package upon arrival. Was it damaged? Was the box crushed? This helps you know whether your products will look professional on delivery.

First attempt delivery success tells you how often packages are delivered successfully on the first try. If the first attempt fails, it causes delays and sometimes leads to extra charges.

Why it matters for exporters: If your products are often fragile or gift-worthy. You need shipping partners who protect my goods and deliver them right the first time.

Red Flags:

- Damaged packaging or crushed boxes arriving at the destination

- A high number of failed delivery attempts leading to rescheduling

- Packages returned to the origin due to missed attempts

6. Average Delivery Time & Lead Time Metrics

Average delivery time gives the typical time taken from pickup to delivery. It helps you compare how fast different partners are.

Lead time metrics cover the full cycle from order confirmation to final delivery, including warehouse handling and customs processing.

How you can use this: Shorter, more predictable times mean I can advertise faster shipping and manage inventory better.

Red Flags:

- Deliveries are taking longer than industry norms without explanation

- No clear visibility into total lead time from dispatch to delivery

- Inconsistent delivery speeds across locations

7. Average Cost per Delivery and Cost per Shipment

Average cost per delivery reflects the overall expense divided across all deliveries, including fixed and variable costs.

Cost per shipment is more specific to each order and helps you understand what I’m spending on an individual basis.

What you should see: The exporters should weigh these against the service quality. Sometimes, a slightly higher cost gives much better results in terms of customer satisfaction.

Red Flags:

- Unexplained cost fluctuations between similar shipments

- Low upfront costs but high hidden fees after delivery

- Lack of clarity in billing or shipment tracking

8. Fuel Consumption Rate and Delivery Mileage Optimization

Sustainability is increasingly important. A lower fuel consumption rate shows that a logistics partner runs a fuel-efficient fleet, which often means fewer emissions and cost savings.

Delivery mileage optimisation indicates how smartly a partner plans their routes to minimise unnecessary driving.

What you should value: Prefer eco-conscious partners, and check if they are efficient in routing, which often leads to faster and cheaper deliveries.

Red Flags:

- Inefficient route planning results in higher fuel costs

- Excessive emissions without sustainability initiatives

- No investment in eco-friendly or fuel-efficient vehicles

9. Vehicle Breakdown Rate and Route Adherence Rate

Vehicle breakdown rate measures how often delivery trucks or vans break down during transit. Frequent breakdowns mean delays, missed deliveries, and unhappy customers.

Route adherence rate shows whether drivers follow pre-planned, optimised delivery routes.

Why you should track this: A company with high vehicle uptime and good route discipline is more reliable and professional.

Red Flags:

- Frequent mechanical issues or missed deliveries due to vehicle failures

- Delivery drivers constantly deviating from planned routes

- High downtime of the delivery fleet

10. Stops per Route Hour and Delivery Time Variance

Stops per route hour tells you how efficient a delivery partner is at completing deliveries in a given time. The higher the number, the more deliveries they can make with fewer resources.

Delivery time variance compares promised vs. actual delivery times. A low variance means the partner is consistent and dependable.

What you should analyse: Efficient delivery schedules reduce waiting time for customers and help you run tighter operations.

Red Flags:

- Few deliveries are completed per hour due to inefficient routing

- High variance in delivery times, making customer planning difficult

- Regular mismatch between promised and actual delivery durations

11. Delivery Complaints Rate, Customer Satisfaction Score and Return Rate Due to Shipping

The delivery complaints rate shows how many customers have had a poor delivery experience.

Customer satisfaction score (CSAT) gives direct insight into how happy recipients are with the delivery service.

Return rate due to shipping tracks how often products are returned due to shipping issues like damage, delay, or incorrect delivery.

Why this is critical: These are real-world reflections of performance. High satisfaction and low complaints give you the confidence to grow with a partner.

Red Flags:

- Escalating number of customer complaints and negative reviews

- Low customer satisfaction scores with no clear resolution plan

- High volume of returns due to shipping issues like damage or delay

When you’re exporting internationally, your shipping partner isn’t just delivering parcels — they’re delivering your brand experience. Choosing the right partner can build your reputation, while the wrong one can quietly damage it over time. Here’s how to tell the difference.

Final Thoughts

Gone are the days when choosing a shipping partner was just a leap of faith. In today’s competitive export landscape, decisions must be grounded in data. With so much riding on timely and flawless deliveries, your brand reputation, customer satisfaction, and even repeat orders, it only makes sense to assess your logistics partner through hard, measurable metrics.

Metrics like on-time delivery rate, order accuracy, route adherence, and customer satisfaction score are not just numbers; they reflect how well your logistics partner understands and supports your business goals. These indicators act like a diagnostic tool, giving you a clear view into a partner’s reliability, efficiency, and overall professionalism.

In the long run, choosing the right delivery partner is an investment in your business’s growth. A trustworthy, efficient, and transparent logistics provider doesn’t just deliver packages; they deliver peace of mind, positive reviews, and loyal customers.

Always remember: your shipping partner isn’t just moving boxes. They’re carrying your brand across borders. Choose wisely, and you’ll have more than just a vendor; you’ll have a strategic ally on your journey to global success.

Frequently Asked Questions

While all metrics matter, the on-time delivery rate is often the most critical, especially for time-sensitive exports. It reflects how reliably the partner can fulfil delivery commitments — a foundational element of customer trust.

Ask for documented performance reports or client references. Reputable partners will be transparent and provide data-backed evidence. You can also cross-check through independent reviews and customer feedback.

A strong perfect order rate usually exceeds 95%, especially in mature logistics networks. Anything below 90% may indicate recurring issues like damages, delays, or incomplete deliveries.

Focus on metrics like delivery condition metrics, order accuracy, and shipping accuracy. Choosing a partner with a low return rate due to shipping ensures fewer issues like damages or wrong deliveries.

Not recommended. Low pricing without visibility into performance is a red flag. Average cost per delivery should be evaluated in balance with reliability, first attempt success, and delivery quality to avoid hidden operational costs.

It’s best to review key delivery metrics at least once a quarter, especially if you’re scaling your exports or entering new markets. Regular reviews help you catch emerging issues early like rising delivery time variance or increasing return rates and give you the chance to hold your partner accountable or explore better alternatives if needed.