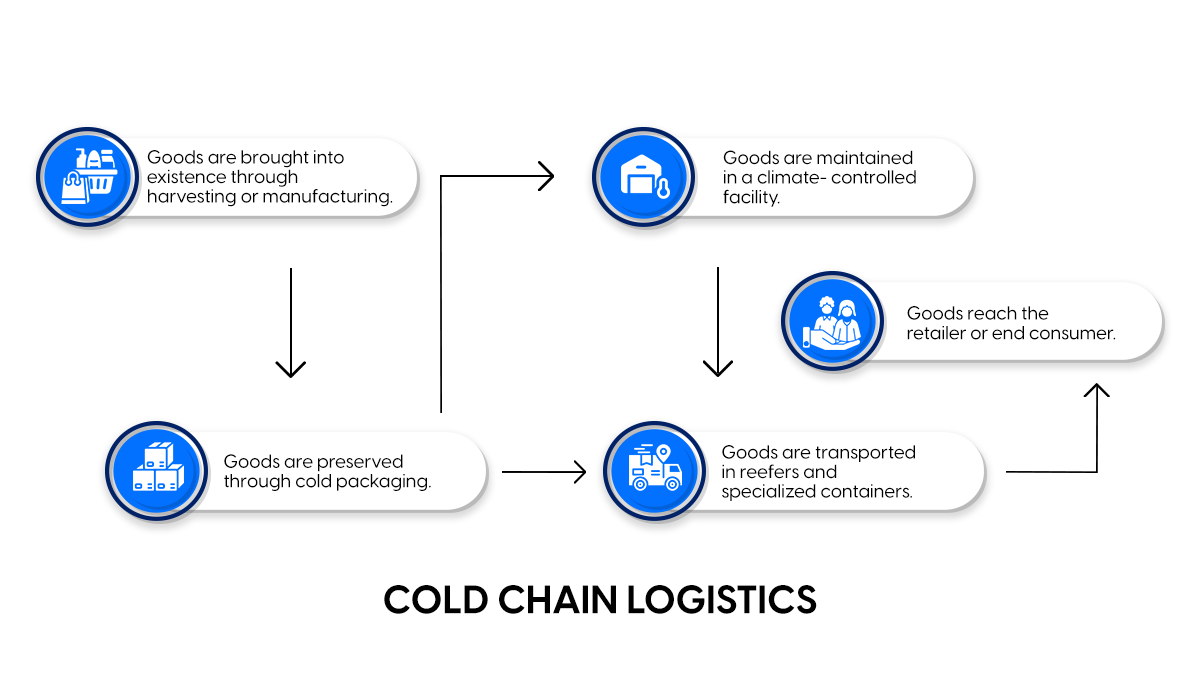

Have you ever wondered how your favorite seafood from Norway or fresh mangoes from India reach your plate without losing their freshness? The answer lies in cold chain logistics for food exports – a behind-the-scenes process that ensures perishable foods exporting items travel across continents while maintaining their quality. Without an efficient global cold chain food spoilage, financial losses, and safety hazards would be inevitable.

Join us as we explore the intricate world of cold logistics, uncover best practices, and reveal how technology is revolutionising the way we transport fresh and frozen food exporting globally.

What is Cold Chain Logistics

A global cold chain is specialised supply chain designed for transporting and storing perishable, temperature-sensitive goods, often referred to as cool cargo. These include fresh fruits, vegetables, meat, dairy products, seafood, pharmaceuticals, chemicals, flowers, and wine.

To preserve the quality and safety of these products, specific temperature ranges must be maintained. Some items require refrigeration, while others need freezing or even ultralow temperatures (deep freeze). If the correct temperature conditions are not upheld, the goods can spoil, leading to financial losses.

Global Cold chain food logistics involves the processes and systems that safely handle and transport these sensitive products from the producer or supplier to the end consumer.

Key Players in the Cold Chain

- Cold Storage Solutions – A temperature-controlled food export warehouse ensures food stays fresh before shipment.

- Refrigerated Transportation – Reefer trucks, shipping containers, and air cargo keep export food at the right temperature.

- Temperature Monitoring – Sensors track temperature fluctuations, ensuring compliance and quality control.

- Supply Chain Coordination – Every step must align perfectly to prevent delays and temperature mishaps.

How to Export Frozen Food Internationally

Exporting frozen food internationally isn’t just about packing it in ice and hoping for the best! Here’s a simple checklist to ensure success:

- Know the Regulations – Different countries have different import laws. Make sure comply with labeling, safety, and packaging standards.

- Use High Quality Packaging – Insulated, vacuum sealed packaging prevents contamination and temperature fluctuations.

- Opt for Cold Storage Solutions: Maintain frozen food in temperature-controlled facilities before shipment

- Monitor Temperature in Transit – Use IoR sensors and GPS tracking to ensure conditions remain optimal.

- Keep Documentation Ready – Customs, food safety, and temperature logs are crucial for smooth clearance.

Following these best practices ensures that your frozen food arrives at its destination in top condition.

Secret to Fresh Food Supply Chain Management

Ever wondered how fresh avocados from Mexico reach Europe without turning brown? It’s all about strategic supply chain management! Keeping export food fresh in transit requires:

- Accurate Demand Forecasting – Avoiding overproduction and waste.

- Smart Inventory Management – Storing only what’s needed to minimize spoilage.

- Optimized Transportation Routes – Reducing transit times through efficient logistics.

- Tech-Driven Monitoring – AI and IoT sensors for real-time quality tracking.

By streamlining these processes, food exporters can ensure their products stay fresh while reducing losses.

Why Temperature Monitoring in Food Exports is a Game Changer

Temperature fluctuations are the biggest enemy of perishable food! A slight change can mean the difference between fresh produce and a spoiled shipment. That’s why temperature monitoring is crucial.

Why it Matters:

- Prevents spoilage and financial losses.

- Ensures compliance with export food safety regulations.

- Provides real-time updates for exporters and buyers. ‘

- Enhances supply chain transparency.

Latest Innovations in Temperature Monitoring

- IoT Sensors and RFID trackers – Real-time alerts on temperature deviations.

- Data Loggers – Keep a history of temperature data for quality checks.

- Cloud-Based Systems – Remote tracking and automated compliance reporting

With these technologies, exporters can confidently ship perishable foods exporting without worrying about spoilage.

Overcoming Challenges in Cold Chain Logistics

Despite it benefits, cold chain logistics comes with hurdles. Let’s tackle some common challenges and their solutions:

- High Costs? – Invest in energy-efficient refrigeration and optimise routes to cut expenses.

- Regulatory Confusion? – Partner with compliance experts to navigate international regulations.

- Infrastructure Gaps? – work with logistics providers that offer global cold storage solutions.

- Temperature fluctuations? – Use AI-powered monitoring to detect and respond to deviations in real time.

- Delays at Customs? – Prepare all necessary documentation in advance to avoid hold-ups

By addressing these challenges proactively, exporters can ensure a smooth cold chain operation.

Future of Cold Chain Logistics: What’s Next

As global demand for fresh and frozen food exporting rises, cold chain logistics is evolving. Here’s what’s coming next:

- Blockchain for Transparency – Improved traceability and fraud prevention.

- AI and Machine Learning – Smarter route planning and temperature adjustments.

- Sustainable Refrigeration: Eco friendly cooling solutions to reduce carbon footprints.

- Automation and Robotics – Faster, error-free food export warehouse operations.

These innovations will make cold chain logistics more efficient, cost-effective, and environmentally friendly.

Final Thoughts: The Key to Fresh, Safe, and Profitable Food Exports

Whether you’re shipping fresh seafood, frozen desserts, or organic produce, an efficient cold chain makes all the difference.

Latest refrigeration and cold chain blogs focus on how exporters are using smart cold storage, real-time temperature tracking, and energy-efficient refrigeration to reduce spoilage during international shipments.

From an exporting perspective, these advancements are helping fresh food exporters maintain product quality across long transit times, meet strict destination country compliance, and lower losses in high-value perishable exports.

Topics like IoT-enabled cold chains, sustainable refrigerants, and integrated cold logistics are especially relevant for exporters shipping fruits, vegetables, dairy, and seafood to global markets.

By leveraging top refrigerated shipping services, cutting-edge temperature monitoring, and strategic supply chain management, exporters can stay ahead in competitive food market. Ready to take your food exports to the next level? Start by optimising your cold chain logistics today!

Without an efficient cold chain, perishable food items would spoil before reaching their destination, leading to financial losses, food waste, and safety hazards. It ensures food stays fresh, meets safety regulations, and reaches consumers in optimal condition.

Temperature monitoring prevents spoilage, ensures compliance, and enhances supply chain transparency. Innovations like IoT sensors, cloud tracking, and AI-driven monitoring allow exporters to maintain consistent temperature control throughout transit.

Temperature monitoring helps by detecting and addressing fluctuations in real time, preventing spoilage and ensuring food remains fresh. Advanced IoT sensors, RFID trackers, and cloud-based monitoring systems provide live updates to exporters, ensuring compliance and transparency.

If the cold chain is broken, perishable food can spoil, lose its nutritional value, or become unsafe for consumption. This can result in rejected shipments, financial losses, and regulatory penalties for exporters.

Register a company, get an IEC, take FSSAI and APEDA registration, follow export quality rules, and arrange logistics to ship fresh food abroad.