Multi-vendor marketplaces simplify complex supply chains by automating vendor coordination, inventory tracking, and procurement. Businesses gain flexibility, speed, and real-time insights while minimizing risk and operational bottlenecks—making them the preferred model for scalable, resilient, and efficient supply chain management.

Think about the last time you went to buy milk and the shelf was empty.

No warning. No explanation.

What if the same thing happens with other things that we use daily?

Pure chaos, right?

Well, most people don’t understand that something as basic as milk or rice depends on a complex supply chain structure. From farmers to vendors, then to transporters, and finally to distributors, before reaching our Kirana stores. If just one link breaks, even for a day, that empty shelf shows up in your life.

Now imagine this same problem at a business level, multiplied across hundreds of products and dozens of vendors.

But do you know that big companies face these small inconveniences every day? And this is why multi-vendor marketplaces are becoming essential for streamlining supply chain operations.

Suppliers, vendors, warehouses and logistics partners are a part of this csmaomplex network that we call the supply chain. With 30-minute delivery becoming a reality and a growing trend nowadays, businesses are expected to deliver faster while managing their costs more effectively, and also remain flexible.

To tackle this complex structure, companies nowadays are moving ahead with the multi-vendor marketplace supply chain model, leaving the traditional system behind.

Businesses now are following a structured system that brings order, automation, and intelligence into supply chain operations. In this blog, you will explore this model, and you will understand why this is the best and most powerful solution for modern businesses.

Growing Complexity of Modern Supply Chains

In this decade, supply chains are no longer limited to one or a single supplier or one particular region for production. Now companies are sourcing raw materials from one place, manufacturing in another and then selling it across countries through multiple marketplaces. The most important thing that makes this successful is faster deliveries, 24/7 availability and transparent tracking.

Now, do you think this all can be managed manually?

Ofcourse no right, because that could risk the flow of the system, resulting in a huge number of errors.

If you are thinking what could go wrong, here’s your answer…

Inventory mismatches, delayed procurement and poor vendor coordination are some of the most common challenges.

These small but major issues make it harder to scale operations and respond quickly to market fluctuations.

This is where multi-vendor ecommerce operations come into play. By consolidating multiple vendors onto a single platform, businesses gain control without sacrificing flexibility.

Multi-Vendor Marketplace Supply Chain

Multi-vendor marketplaces brings supply chain together through multiple suppliers and sellers under one umbrella that is one digital ecosystem.

A multi-vendor marketplace supply chain brings together multiple suppliers and sellers under one digital ecosystem. Each vendor operates independently, but the marketplace platform manages coordination, data flow, and operational rules.

Dealing with separate systems for procurement, inventory, and order fulfilment can be tough; that is why businesses use one centralised platform. This model supports scalability while keeping processes consistent and transparent.

The marketplaces act as a backbone of operations, which makes sure communication is mother and division-making is faster throughout the supply chain.

The marketplace acts as the backbone of operations, enabling smoother communication and faster decision making across the supply chain.

Multi Vendor e-Commerce Operations Improve Efficiency

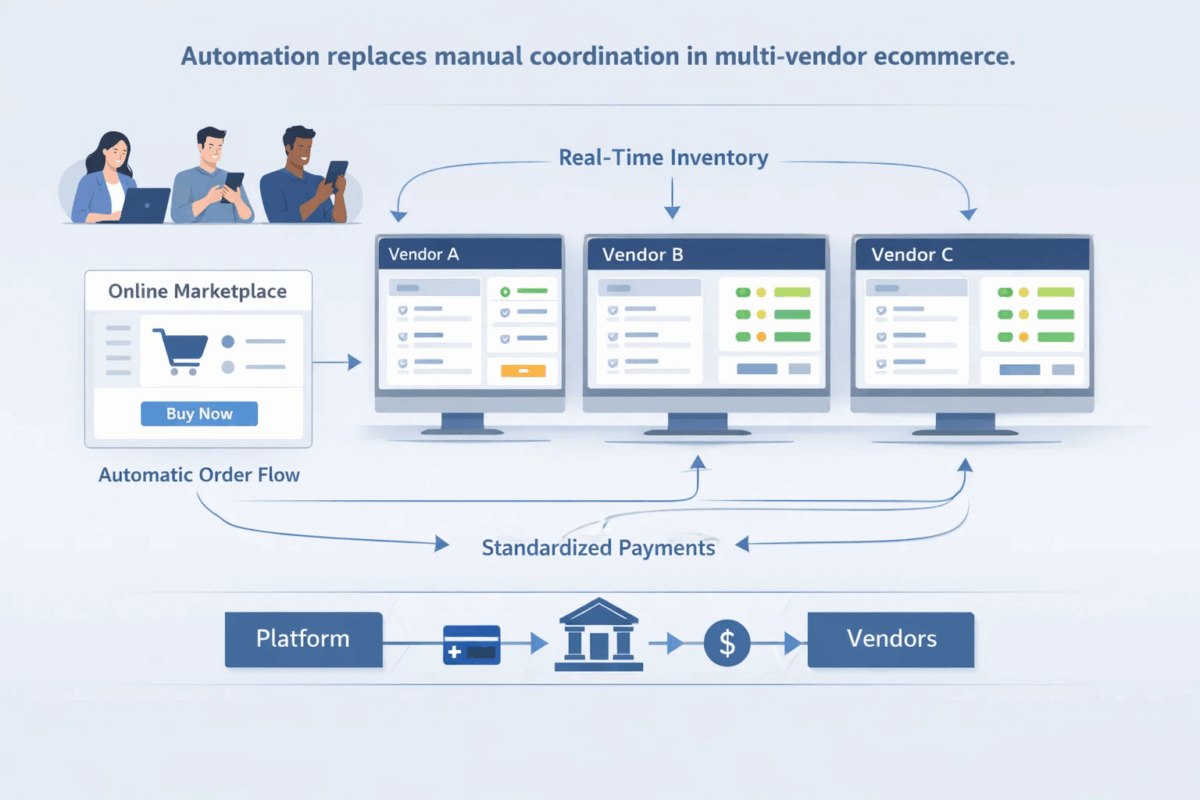

One of the biggest advantages of multi-vendor ecommerce operations is efficiency. Traditional supply chains rely heavily on manual coordination, emails, spreadsheets, and phone calls. This slows things down and increases the chance of mistakes.

Efficiency is one of the biggest advantages of multi-vendor ecommerce operations, making sure the flow is smooth.

A marketplace setup should have:

- Automatic orders flowing from customers to vendors

- Real-time inventory updates

- Standard and secure settlements and payments

This flow will reduce friction between multiple stakeholders and will allow multiple teams to focus on major growth rather than resolving operational issues.

Centralised Purchase Management without Losing Control

Imagine what will happen if, in this multi-vendor flow, you lose control. Even one step can result into major disturbance to the supply chain.

Centralising the whole management process makes it possible for businesses to maintain and watchout all activities like procurement while managing multiple vendors at the same time. Approvals for purchase, selection for the perfect supplier and tracking orders can all be managed in one place.

This approach helps:

- Tracking spends across vendors

- In enforcing procurement policies

- Compare supplier performance easily

At the same time, teams can quickly switch vendors when needed, ensuring flexibility without chaos.

Vendor Management Automation Simplifies Scaling

With time, vendor networks are growing, and manual management is becoming unsustainable. That is why vendor management automation is the need of today’s time.

As vendor networks grow, manual management becomes unsustainable. This is where vendor management automation becomes essential.

Automation streamlines key vendor-related tasks such as:

Here’s how automation will streamline key vendors and tasks related to them:

- New vendors onboarding

- Contracts management

- Managing service level agreements (SLA’s)

- Updating prices and catalogues

- Monitoring fulfilment performances

By automating these processes, marketplaces reduce administrative effort and ensure consistency across vendors. This makes it easier to scale operations without increasing operational costs proportionally.

Achieving Real-Time Inventory Visibility Across Vendors

Do you know what the most critical and vital aspect of supply chain efficiency is?

Well, it’s Inventory visibility

To make any supply chain efficient, inventory visibility is vital. Another important aspect of this is data which is not fragmented, which usually leads to outdated and inaccurate information.

Multi-vendor marketplaces solve this by offering real-time inventory visibility. Inventory levels from all vendors are synced continuously to the platform, providing a single source of truth.

This helps businesses to:

- Avoid selling out-of-stock items.

- Reduce excess or extra inventory.

- Taking a fulfilment decision only if needed.

This data also helps in improving customer trust by making sure that accurate delivery timelines can be scheduled.

Enabling Multi-Supplier Procurement Strategies

Risk increases when you rely on a single supplier, which eventually results in delays, shortages and quality issues that disrupts teh entire supply chain in the future.

Multi-vendor marketplaces support multi-supplier procurement, allowing businesses to source the same product from multiple vendors. This creates healthy competition and ensures continuity of supply.

When you choose multi-supplier procurement, businesses can:

- Lead time and compare prices

- Balance volumes of orders across vendors

- Reduce dependency on one specific supplier

This way, things will improve resilience and will help in maintaining service levels even during major or minor disruptions.

Intelligent Order Routing Across Vendors

Another major area where markeplecs add significant and extra value. Instead of manually assigning traditional orders assigning manually, the platforms can automate order routing for all vendors.

The system can route orders based on:

- Inventory availability

- Vendor location

- Delivery timelines

- Cost efficiency

This ensures that each order is fulfilled by the most suitable vendor, improving delivery speed and reducing logistics costs. Customers receive their orders faster, and vendors operate more efficiently.

Using Marketplace Data for Demand Forecasting

One of the best things about a marketplace model is that it gives you access to aggregated data. Marketplaces gather data from many sellers and buyers, unlike systems that only work with one seller.

Businesses can look at trends on a much larger scale when they use marketplace data to predict demand. Better forecasts come from looking at past sales, seasonal demand, and regional preferences.

Accurate demand forecasting helps:

- Optimise inventory levels

- Plan procurement more effectively

- Reduce waste and overstocking

Data-driven planning gives you insights instead of guesswork, which makes the whole supply chain work better.

Improving Supply Chain Agility and Flexibility

Multi-vendor marketplaces make supply chains more flexible and agile by letting them respond to changes more quickly. With little trouble, orders can be sent to a different location, suppliers can be changed, and inventory can be moved around.

This flexibility is especially important in fields where how quickly and easily goods can be delivered affects how happy customers are. Data-driven planning gives you insights instead of guesses, which makes the whole supply chain work better.

Making the supply chain more agile and flexible. Markets change quickly. You might not have much time to prepare for spikes in demand, supply problems, or logistics issues.

By allowing for faster responses to these changes, multi-vendor marketplaces make the supply chain more flexible and agile. You can change suppliers, move orders around, and move inventory around with little trouble. This flexibility is especially important in fields where how quickly and easily things can be delivered affects how happy customers are.

Risk Mitigation in Supplier Networks

Supplier risk is a big worry for businesses today. Relying too much on one vendor can cause big problems in supply chains.

Marketplaces help reduce risk in supplier networks by spreading sourcing across many vendors. If one supplier has problems with their operations, other suppliers can step in to meet demand.

This kind of distributed approach:

- Reduces single points of failure

- Improves continuity of supply

- Strengthens long-term resilience

Risk mitigation becomes built into the system rather than handled reactively.

Operational Benefits Beyond Cost Savings

While cost reduction is a major benefit, multi-vendor marketplaces offer much more than savings.

They help businesses:

- Improve operational transparency

- Enhance supplier collaboration

- Scale efficiently without complexity

- Deliver better customer experiences

The combination of automation, visibility, and data creates a more predictable and controllable supply chain environment.

Multi-vendor marketplace model is the future. As supply chains get more complicated, old models have a hard time keeping up. Companies need systems that can change, grow, and use data to make decisions.

The multi-vendor marketplace supply chain model meets these needs by making things more organised. It lets companies handle many vendors, get the best deals on purchases, and quickly fill orders all from one place.

This is why more businesses are putting money into strong multi-vendor ecommerce operations as a long-term strategy instead of a quick fix.

Final Thoughts

Multi-vendor marketplaces are more than just places to buy and sell things online. They are becoming very important parts of how supply chains work today.

These platforms help businesses stay competitive in a market that is getting more and more demanding by allowing automated vendor management, real-time inventory visibility, multi-supplier procurement, and smart order fulfilment.

For businesses that want to work more efficiently, lower their risk, and grow in a way that is good for the environment, using a marketplace-driven approach to supply chain management makes sense.

Frequently Asked Questions (FAQ’s)

A multi-vendor marketplace supply chain is a digital model where multiple suppliers and vendors operate on a single platform, allowing businesses to manage procurement, inventory, orders, and fulfilment in one unified system.

It replaces manual coordination with automation, enabling real-time inventory updates, automatic order routing, and standardised payments, which reduces errors and speeds up operations.

Real-time visibility prevents overselling, reduces excess inventory, improves delivery accuracy, and provides a single source of truth across all vendors.

By sourcing from multiple vendors, businesses avoid dependency on a single supplier, ensuring continuity of supply even when one vendor faces disruptions.

Yes. Automation in vendor onboarding, order management, and performance tracking allows businesses to scale vendor networks without increasing operational complexity or costs.