Managing and keeping track of your inventory can be a tedious process, and involves many challenges.

But not for Shagun.

Shagun runs a thriving fashion accessories business on multiple platforms—Amazon, Etsy, and her own website. But things were not always smooth for her. Managing inventory manually proved to be a nightmare. She often oversold items, leading to unhappy customers and negative reviews.

You must be thinking how she turned her situation around to establish a successful business.

Shagun used the power of AI and automation to manage her inventory efficiently. She discovered AI-powered inventory management tools that helped her better streamline the operations.

Now, instead of stressing over stock levels, Shagun focuses on expanding her business and delivering excellent customer service.

Can you relate to Shagun’s struggles and want to run your business just like her? If so, it might be time to consider AI for your operations.

Keep reading to know how AI and automation in multichannel inventory management can prove to be a game changer for your business.

What is Multichannel Inventory Management

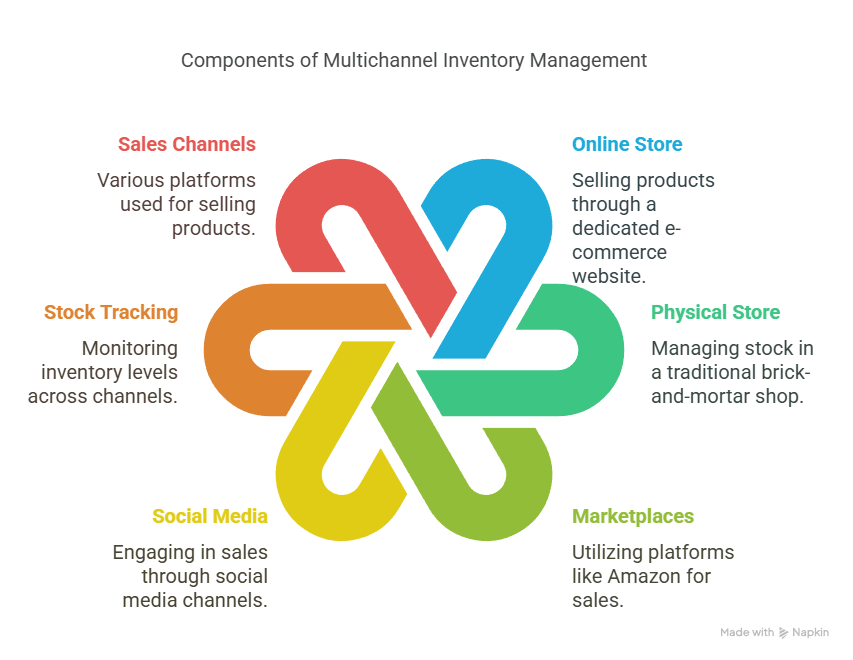

Before understanding the implication of AI and automation in inventory management, let’s first break down what multichannel inventory management is.

Multichannel: It refers to the different channels you use to sell your products—be it an online store, a physical shop, marketplaces like Amazon, or even social media platforms.

Inventory Management: This is all about keeping tabs on your stock. It involves tracking purchases, sales, returns, and even moving inventory between different locations.

Simply put, multichannel inventory management is the smart way of tracking and managing stock across multiple sales platforms such as online marketplaces, physical stores, and eCommerce websites. It’s about keeping an eye on inventory levels and optimising stock across every sales channel you use.

Imagine selling on Amazon, Shopify, and your own website—multichannel inventory management ensures you don’t oversell or run out of stock. Sounds useful, doesn’t it?

The big idea here? To have one clear, accurate source for all your inventory data—no confusion, no guesswork.

Growing Need for AI in Multichannel Inventory Management

Managing inventory across various sales channels can be overwhelming.

Ever wondered how big companies manage their stock so efficiently? AI driven solutions provide them with real-time insights and predictive analytics. This helps them stay ahead of demand fluctuations and avoid stockouts or excess inventory.

In today’s world, businesses of all sizes need to maintain accurate stock levels to prevent overselling and fulfill orders on time. The use of automation tools and AI powered systems in inventory management can help analyse tons of data to identify trends and patterns. This allows businesses to make smarter decisions. Pretty cool, right? These insights help in smarter procurement, inventory allocation, and replenishment strategies that reduce waste and boost profitability.

Why Should You Care About Automation in Inventory Management

Let’s face it, keeping track of inventory manually can be extremely challenging and error prone. Automation simplifies complex inventory management tasks by integrating various systems and processes into a seamless workflow. Here’s how AI and automation make the experience different for you:

- Optimize Stock Levels: AI driven demand forecasting predicts future demand based on past sales data, helping you maintain optimal inventory levels.

- Improve Order Accuracy: Say goodbye to costly human errors! Automated systems ensure precise order fulfillment and operational efficiency.

- Enhance Customer Satisfaction: Fast processing times and accurate stock updates lead to happy customers and positive reviews. Isn’t that what we all want?

- AI-Driven Demand Forecasting for Smarter Planning: Implementing demand forecasting helps businesses adjust purchasing, marketing, and stocking strategies based on expected customer demand. When powered by automation, these forecasts become even more accurate and actionable.

- Integrated Forecasting and Automation Benefits: Businesses that integrate demand forecasting and automation into their inventory systems experience better decision-making, reduced carrying costs, and enhanced customer satisfaction due to improved product availability.

Comparison Table: Non-Automated Vs Automated Inventory Management

| Aspect | Non Automated Inventory Management | Automated Inventory Management |

| Data Tracking | Manual tracking via spreadsheets, paper logs, or manual updates. | Real-time tracking through software and digital systems. |

| Accuracy | Prone to human errors in data entry and record-keeping. | High accuracy with minimal errors due to automation. |

| Time Efficiency | Time-consuming processes like counting and manual updates. | Quick and efficient with automated updates and reports. |

| Labor Requirement | Requires more staff for data entry, stock counts, and management. | Reduces dependency on manual labor; employees focus on analysis and strategy. |

| Inventory Visibility | Limited visibility; data may be outdated or inconsistent. | Real-time visibility across all locations and sales channels. |

| Error Management | Errors are harder to detect and fix, leading to potential losses. | Errors are quickly identified and minimized through automated systems. |

| Scalability | Difficult to scale due to manual processes. | Easily scalable as automation handles large data volumes effortlessly. |

| Cost Efficiency | Lower initial cost but higher operational costs due to inefficiencies. | Higher upfront investment but reduced long-term costs due to optimized operations. |

| Demand Forecasting | Limited ability to forecast accurately; relies on manual analysis. | Advanced forecasting using AI and analytics tools for better demand planning. |

| Inventory Turnover | Slower turnover due to delays in stock updates and inefficiencies. | Faster turnover with real-time updates and insights for decision-making. |

| Integration | Difficult to integrate with multiple sales channels or systems. | Seamlessly integrates with eCommerce platforms, ERP, and other tools. |

| Customer Satisfaction | Delays and stockouts can negatively impact customer experience. | Accurate inventory ensures timely delivery and better customer satisfaction. |

| Stock Optimization | Overstocking or understocking is common due to lack of real-time data. | Optimal stock levels maintained with automated alerts and tracking. |

| Technology Use | Minimal or no use of advanced technology. | Leverages barcodes, RFID, WMS, and AI for seamless operations. |

How to Implement AI Powered Solutions for Inventory Optimisation

So, how can you get started with AI in multichannel inventory management? Here are some smart tools to consider:

- Smart Inventory Tracking: Use advanced inventory tools like Zoho Inventory and QuickBooks Commerce after assessing your business needs. These platforms leverage automation to monitor stock levels in real time across multiple sales channels, reducing discrepancies and ensuring accurate data.

- Automated Order Processing: Embrace automation to streamline order fulfillment without manual intervention. By automating repetitive tasks like invoicing, order entry, and stock updates, businesses can significantly reduce human error and speed up delivery times.

- Demand Forecasting: AI-driven demand forecasting models analyze historical data, seasonal trends, and buying behaviors to predict future inventory needs. This helps in preventing stockouts or overstock situations, optimizing warehouse space, and boosting profitability.

- Predictive Analytics with Automation: AI tools combine predictive analytics and automation to not only track current stock levels but also suggest reordering times and quantities based on real-time trends. This blend ensures a responsive and agile supply chain.

Challenges of Using AI and Automation for Inventory Management

Of course, no solution is perfect. Implementing AI and automation in inventory management can come with a few challenges. Here are some key challenges you should consider:

| Challenges | Explanation |

|---|---|

| Integration Complexities | Connecting AI systems with your existing tools might take some effort. |

| Data Accuracy | AI is only as good as the data it receives. Make sure your records remain up to date to avoid errors. |

| Employee Training | Educate and train your team about how to use these tools effectively. |

| High Cost | Implementing AI solutions require a significant initial investment. |

Future of AI in Inventory Management

By embracing AI and automation, businesses can stay ahead of the competition, work more efficiently, and keep customers coming back for more. Here’s what’s next for AI in inventory management:

- Smarter features, like machine learning algorithms that anticipate demand with near-perfect accuracy.

- Blockchain for transparent supply chains.

- IoT devices that provide real-time updates from warehouses.

- Mobile First Solutions (mobile applications) to keep track of stock, manage shipments, and get real time notifications — all from your smartphones.

- AI can boost sustainable and green supply chain practices by helping optimise inventory levels and reducing waste.

Conclusion

In today’s fast-paced eCommerce world, businesses must adapt to the growing complexity of managing stock across multiple platforms, including online marketplaces, brick-and-mortar stores, and direct-to-consumer websites.

Managing inventory efficiently is like mastering the art of juggling. If you don’t want to run out of stock or have “where did all the stock go?” moments you’ve got to keep a balance of everything. The key? Smarter systems and fewer headaches.

Adopt automation and AI in multichannel inventory management to remain stress-free and keep your inventory game on point. These solutions enable businesses to optimise stock levels, meet customer demands, and streamline fulfillment processes like never before. The benefits — get real time stock updates across all channels, automated demand forecasting, and happy customers.

Take your inventory management to the next level with AI and see your business transform with the help of these solutions.

FAQs

Multichannel inventory management refers to tracking and managing stock across various sales platforms like an eCommerce store (Amazon, Shopify, etc.) or a physical store, ensuring accurate stock levels and preventing overselling.

AI analyzes historical and real-time data to forecast demand, optimize stock levels, and automate repetitive tasks, reducing errors and improving efficiency.

Automation offers real-time inventory tracking, faster order fulfillment, reduced operational costs, and increased accuracy in stock management.

Challenges include integration complexities, data accuracy issues, employee training requirements, and high initial costs for implementation.

Yes, automation tools are scalable and can benefit small businesses by saving time, reducing errors, and allowing them to focus on growth rather than manual tasks. These tools prove to be cost-effective in the lung run.

Yes, automation streamlines order processing through systems like conveyor belts and robotic picking, enabling faster order fulfillment compared to manual methods in non-automated warehouses.