Out-of-stock (OOS) products are one of the biggest conversion killers in ecommerce. Every time a customer lands on an unavailable product, the risk of losing a sale and possibly the customer increases dramatically. But it doesn’t have to be that way.

With the right strategies, you can Handle Out-of-Stock Products in Ecommerce in a way that preserves user experience, prevents frustration, and even drives additional revenue.

This guide breaks down everything you need to know: from customer communication, alternative product suggestions, and back-in-stock alerts to more advanced inventory forecasting methods like predictive inventory analytics, reorder point optimization, and safety stock calculation.

Let’s dive in.

Why Out-of-Stock Situations Hurt More Than You Think

When a product goes out of stock, here’s what often happens:

- Customers leave without buying anything

- They turn to competitors

- Cart abandonment spikes

- Trust weakens due to poor communication

- Inventory planning struggles continue behind the scenes

But the good news? You can flip the script by being proactive, transparent, and strategic.

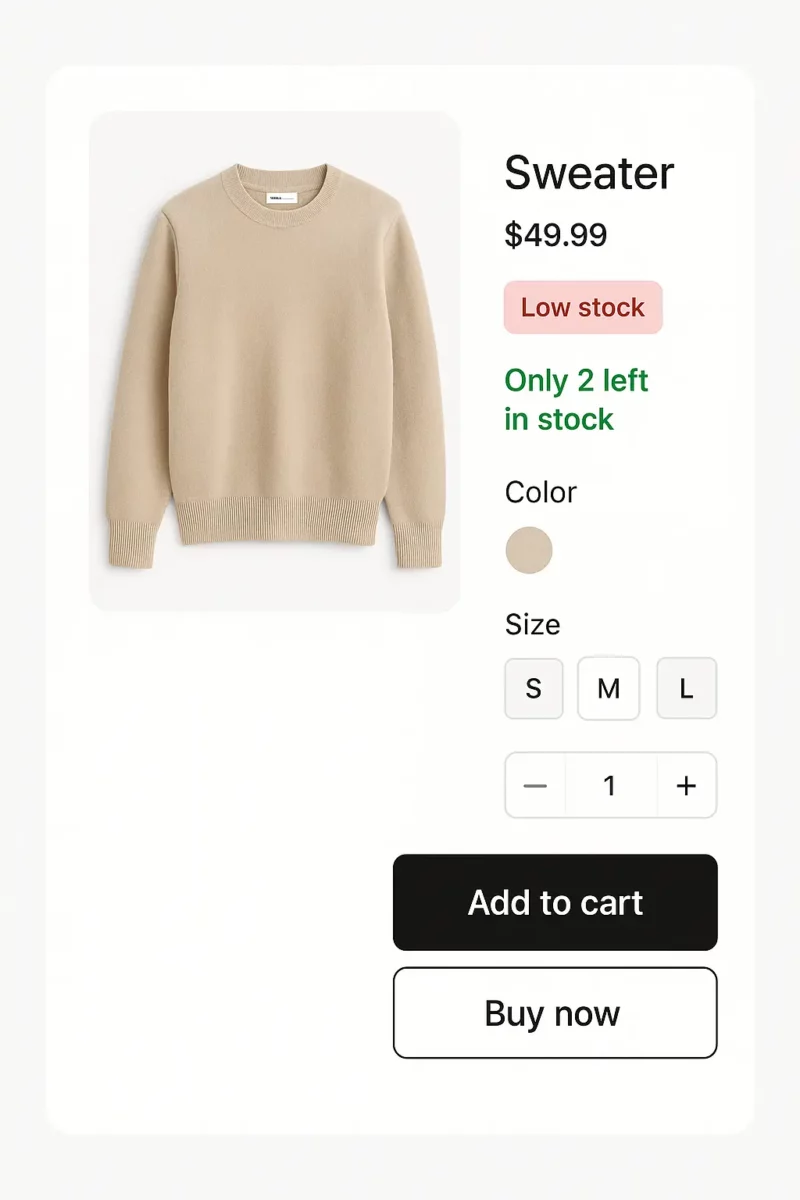

1. Be Transparent About Stock Levels

Shoppers appreciate honesty. One of the simplest ways to improve OOS experiences is to increase transparency in stock levels throughout the store:

- Display “Only X left” real-time stock counters

- Show estimated restock dates when possible

- Add badges such as Low Stock, Selling Fast, or Restocking Soon

This level of transparency reduces customer frustration and supports your broader customer retention strategies.

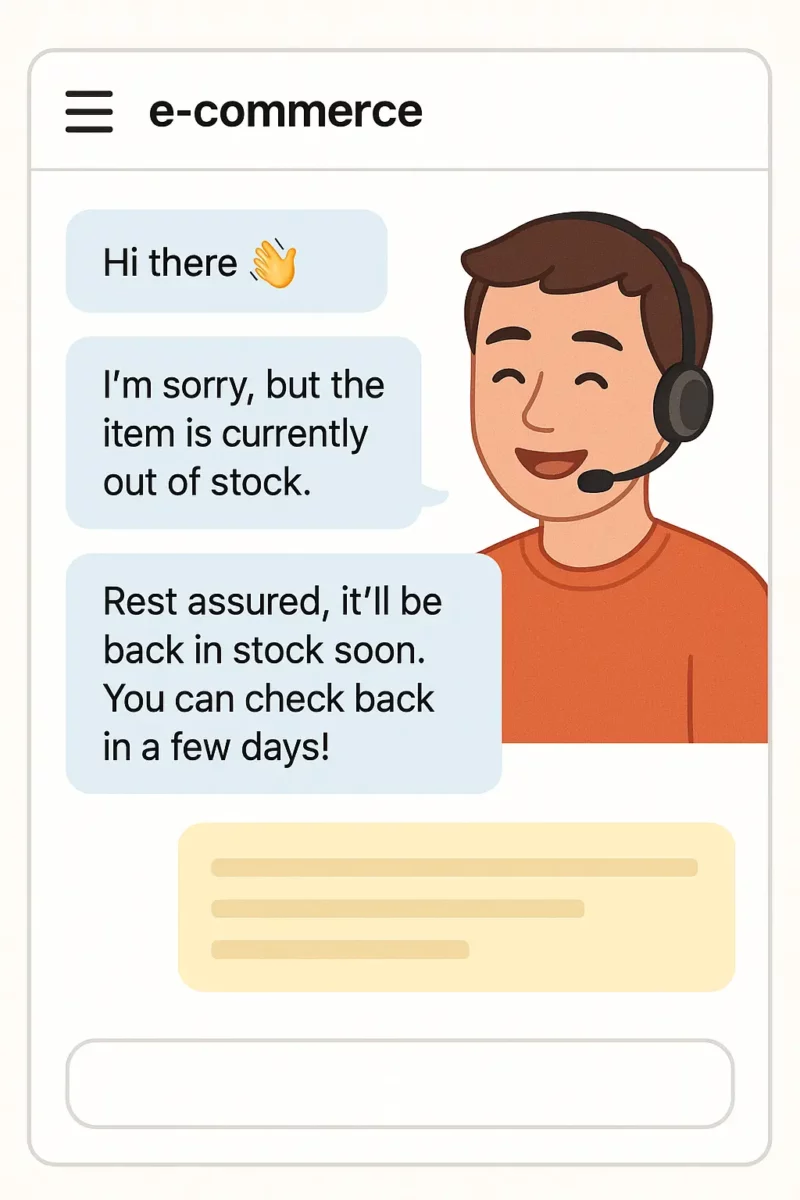

2. Improve Customer Communication for OOS Situations

Clear, empathetic, and proactive customer communication for OOS products helps maintain trust. Instead of blindsiding customers with surprise unavailability, offer:

- Friendly explanations

- Expected restock timelines

- Options to stay informed

- Choices (more on that next)

Simple message examples:

- “This product will be back soon – join our waitlist to get notified instantly!”

- “Demand was higher than expected, but we’re restocking. Here’s what else we recommend in the meantime.”

This style of communication humanizes your brand and reduces negative sentiment.

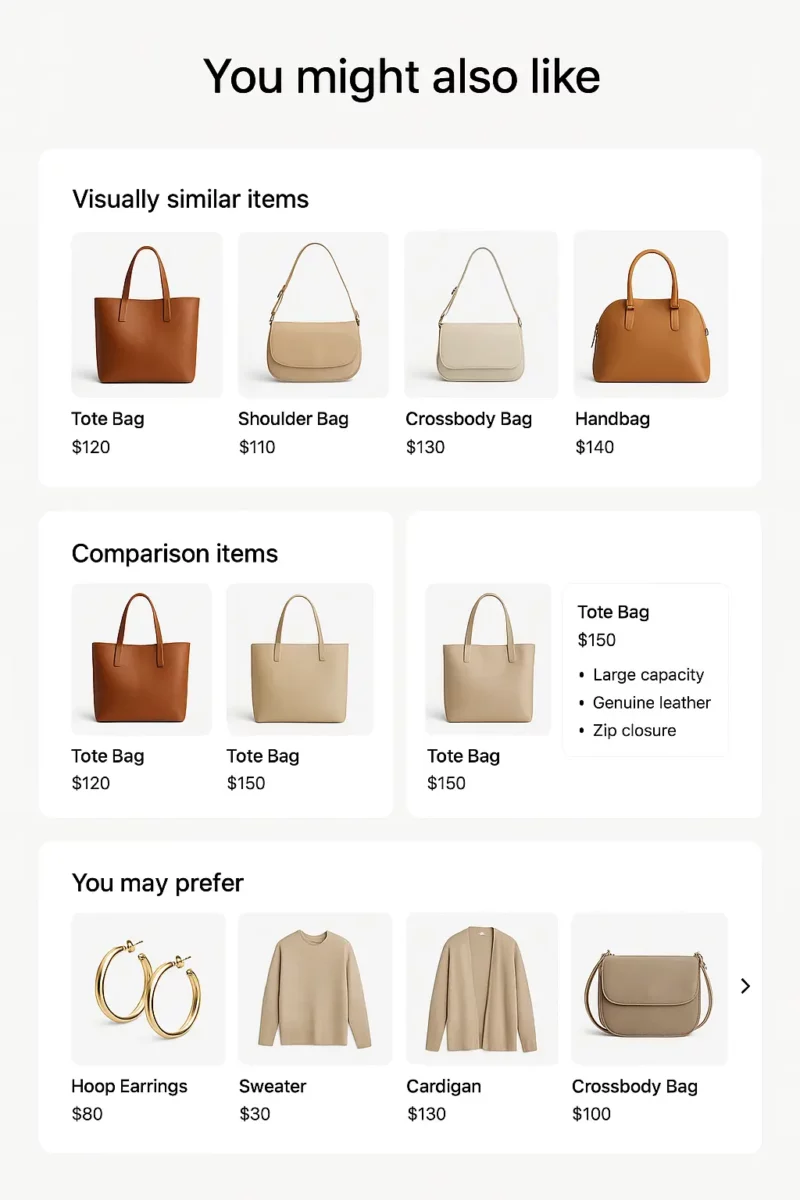

3. Provide Smart Alternative Product Suggestions

Never let an OOS product become a dead-end. Offering alternative product suggestions keeps customers engaged and can save the sale.

Examples include:

- Similar items with comparable features

- Newer models or upgraded versions

- Bestsellers in the same category

- User-personalized recommendations based on browsing history

These alternative recommendations should appear in multiple places:

- Product pages

- Search pages

- Pop-ups

- Cart pages

Done right, this strategy can significantly reduce drop-offs and increase conversions.

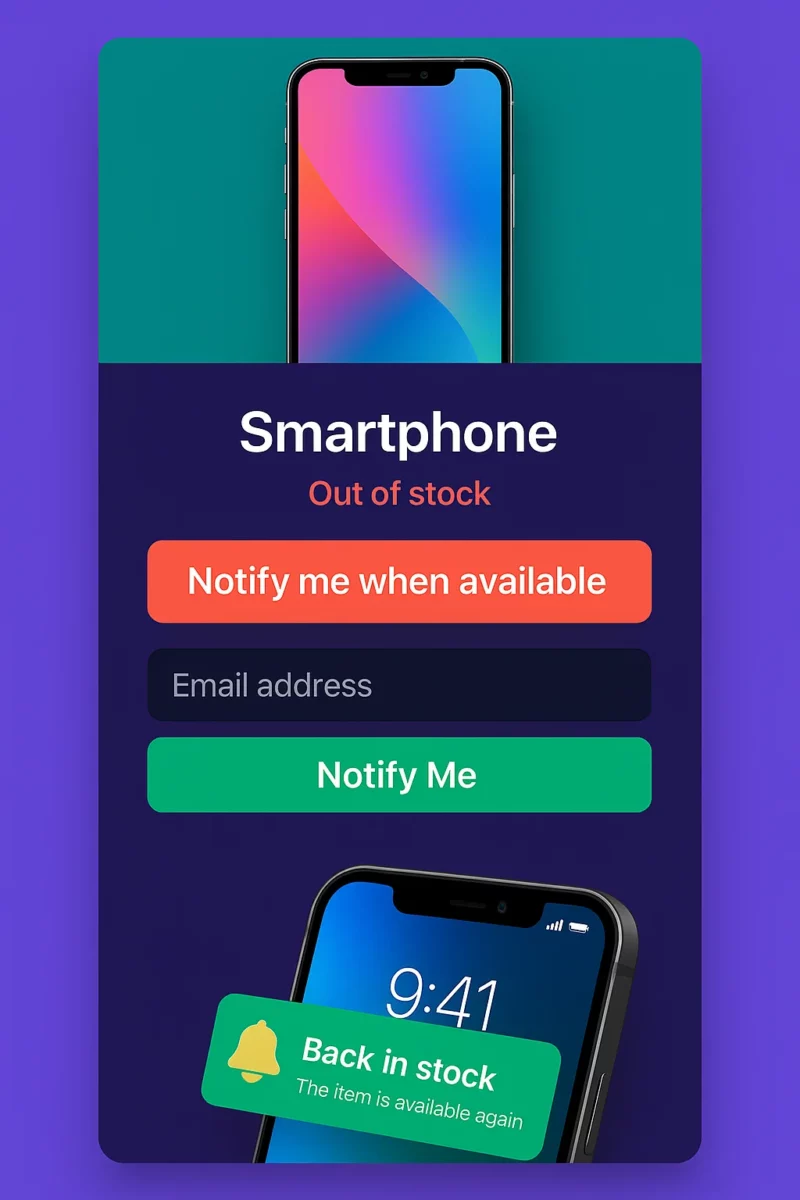

4. Add a “Notify Me” Feature and Back-in-Stock Alerts

The notify me feature is one of the most effective tools for revenue recovery. It collects user interest and automatically sends back-in-stock alerts when inventory is replenished.

Why it works:

- You capture intent instead of losing it

- Customers feel valued and informed

- It boosts conversion rates the moment stock returns

Pro tips:

- Offer both email and SMS alerts

- Add urgency: “Limited quantity available – claim yours soon.”

- Keep the signup process frictionless

This strategy also supports demand forecasting, since waitlist size indicates interest.

5. Offer Preorders or Reserve Options (When Appropriate)

If the product returns soon, give customers the chance to:

- Preorder

- Reserve their unit

- Purchase now and ship later

Make sure to communicate clearly about timelines, cancellation options, and expected delivery dates.

This strategy prevents cart abandonment, captures revenue earlier, and improves customer experience.

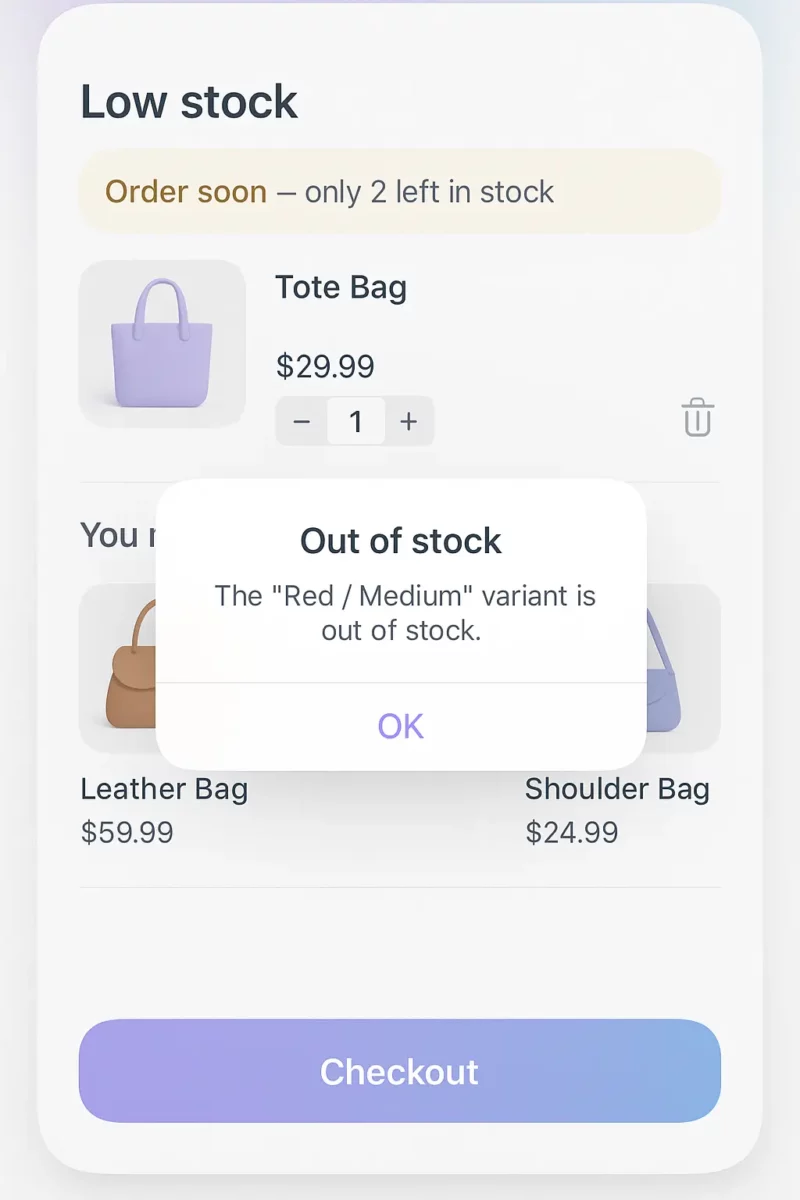

6. Prevent Cart Abandonment with Smart UX

Out-of-stock surprises during checkout are incredibly frustrating. Improve the experience with:

- Automatic OOS alerts in the cart

- One-click product swaps

- “Remind me later” options

- Variant suggestions when one size/color is unavailable

- Inline low-stock warnings

All these small touches support cart abandonment prevention and reduce friction during checkout.

7. Strengthen Your Demand Planning Strategy

Behind the scenes, your operational planning determines how often OOS situations happen. To reduce stockouts long-term, invest in a stronger demand planning strategy supported by accurate forecasting.

Forecasting Insights: Stay Ahead with Data

| Forecast Focus | Strategy |

|---|---|

| Future Demand Spikes | Use historical data and AI models to predict surges based on promotions, festivals, or market signals. |

| Seasonal Shifts | Identify year-over-year trends and climate-influenced seasonality to plan inventory by region and time. |

| Emerging Buying Patterns | Analyze real-time analytics and sentiment data to detect shifts in preferences (e.g., sustainability, diet). |

| Low-Stock Risks | Set smart reorder points using sales velocity and lead times to avoid out-of-stock scenarios. |

📊 Powered by data, driven by insights — prepare, stock, and scale smartly.

A strong planning strategy reduces surprises and improves supply chain resilience.

8. Use Predictive Inventory Analytics for Better Forecasting

One of the most powerful ways to minimize stockouts today is through predictive inventory analytics.

Forecasting Insights: Stay Ahead with Data

| Forecast Focus | Strategy |

|---|---|

| Future Demand Spikes | Use historical data and AI models to predict surges based on promotions, festivals, or market signals. |

| Seasonal Shifts | Identify year-over-year trends and climate-influenced seasonality to plan inventory by region and time. |

| Emerging Buying Patterns | Analyze real-time analytics and sentiment data to detect shifts in preferences (e.g., sustainability, diet). |

| Low-Stock Risks | Set smart reorder points using sales velocity and lead times to avoid out-of-stock scenarios. |

📊 Powered by data, driven by insights — prepare, stock, and scale smartly.

Better sales forecasting accuracy translates into better purchasing decisions, fewer surprises, and improved customer experience.

9. Nail Reorder Point Optimization

Reorder points shouldn’t be guesswork.

Reorder point optimization ensures you reorder stock before you reach critically low levels. Using lead time + demand variability, you can calculate an exact trigger point for reordering.

What Forecasting Helps You Avoid

| Challenge | How Forecasting Prevents It |

|---|---|

| Emergency Restocks | Advanced planning ensures inventory is replenished on schedule without last-minute logistics stress. |

| Excess Inventory | Data-driven forecasting prevents over-ordering by matching supply to realistic demand patterns. |

| Missed Sales (Stockouts) | Real-time stock alerts and predictive modeling keep your bestsellers available when customers want them. |

✅ Stay lean, stocked, and sales-ready — all thanks to smart forecasting.

Optimize this per SKU, especially for high-demand items.

10. Calculate Safety Stock Strategically

Safety stock calculation helps you maintain a buffer inventory that protects against unexpected demand or supplier delays.

How to Calculate the Right Inventory Level

| Factor | Why It Matters |

|---|---|

| Measure Demand Variability | Understand how much demand fluctuates over time to determine safety stock and avoid understocking. |

| Track Supplier Reliability | Know which suppliers consistently deliver on time to plan buffer stock accordingly. |

| Consider Lead-Time Fluctuations | Account for shipping or production delays by adjusting reorder points based on average lead times. |

📦 Right level = right time + right quantity. Accuracy starts with insight.

With proper safety stock, you dramatically reduce the likelihood of OOS events.

11. Increase Your Inventory Turnover Improvement Rate

High inventory turnover means your stock is flowing efficiently.

Low turnover often leads to shortages in key SKUs while less-needed items pile up.

Smart Tactics to Optimize Inventory

| Tactic | Description |

|---|---|

| Demand-Based Restocking | Replenish inventory based on sales velocity and forecasts instead of set cycles. |

| Phasing Out Underperforming Variants | Identify slow movers and reduce orders or discontinue to free up shelf space and capital. |

| Running Clearance Campaigns | Move aging or excess stock through discounts, bundles, or limited-time offers. |

| Improving SKU-Level Analytics | Monitor individual SKU performance to make precise decisions on stocking, pricing, and marketing. |

📈 Smarter tactics = leaner inventory, higher profits, happier customers.

This boosts overall inventory turnover improvement and frees up cash for the products customers actually want.

12. Turn OOS Moments Into Customer Retention Opportunities

Retain Loyalty Even When Items Are Unavailable

| Retention Tactic | Impact |

|---|---|

| Personalized Back-in-Stock Emails | Keep customers engaged and feeling valued by alerting them when desired items return. |

| Exclusive Alerts for Loyal Customers | Reward loyalty with early-access restock notifications or members-only alerts. |

| Small Incentives (e.g. Free Shipping) | Offer perks like free shipping or discounts when an item is restocked to convert interest into purchase. |

💌 Missed a sale? Win hearts anyway with proactive communication and small gestures.

These customer retention strategies ensure people return rather than defecting to competitors.

Conclusion: Out-of-Stock Doesn’t Have to Mean Out-of-Sale

OOS situations are inevitable – but losing customers over them is not.

When you combine smart communication, alternative suggestions, strong forecasting, predictive analytics, and UX enhancements, you can Handle Out-of-Stock Products in Ecommerce smoothly and profitably.

Out-of-stock moments become opportunities:

- To build trust

- To capture future sales

- To deepen customer relationships

- To optimize operations

- To prevent future stockouts through better forecasting

FAQs

They interrupt buying intent and push shoppers to competitors

No, keep the page live and offer alternatives or notifications.

Use a simple notify me feature or back-in-stock alerts via email/SMS.

Similar items recommended when the original product is unavailable.

Data-driven forecasting to predict demand and prevent stockouts.

Use demand + lead time variability to maintain a buffer.

Setting the right inventory level to trigger reordering before stock runs out.

Show alternatives, offer notifications, and warn early about low stock.